Ice Maker Making Slushy Ice? Fix It Fast

This post contains affiliate links. As an Amazon Associate, we earn from qualifying purchases.

Your ice maker churns out watery slush instead of satisfying nugget ice, melting into puddles before you even reach for a drink. After running vinegar cycles and distilled water flushes for hours, you’re left with zero solid ice and mounting frustration. This isn’t normal operation—it’s a clear signal your Euhomy IM-12S-HM has lost its freezing capability. You’ll discover exactly why mineral buildup, temperature miscalibration, or condenser issues sabotage ice formation and get actionable steps to fix ice maker making slushy ice permanently. Skip the guesswork—these field-tested solutions restore solid ice production within one day.

Why Your Ice Maker Makes Slush Instead of Solid Nuggets

Slush formation means your evaporator plate can’t reach the critical 0–5 °F range needed for solid ice. When mineral deposits insulate the freezing surface or temperature sensors miscalculate cycle completion, water fails to fully crystallize. Your Euhomy IM-12S-HM specifically requires 10–15 °F for proper nugget formation—just 5 degrees warmer than cube makers but still demanding precise thermal control. If ambient temperatures exceed 85 °F or condenser coils are clogged, the system simply can’t shed enough heat to achieve these temperatures.

Temperature Thresholds That Determine Ice Quality

Solid Nugget Formation: 10–15 °F (-12 to -9 °C)

Slush Formation: Above 15 °F (-9 °C)

Complete Failure: 32 °F (0 °C) and higher

Even slight deviations above 15 °F cause partial melting during the harvest cycle. The evaporator plate must consistently hit freezing temperatures before water release—mineral scale or sensor errors disrupt this delicate timing. If your thermometer reads above 15 °F in the ice bin after 6 complete cycles, component failure is likely.

Eliminate Mineral Buildup Causing Slush Formation

Mineral deposits from tap water create a thermal barrier on the evaporator plate, preventing proper heat transfer. This is the #1 cause of slushy ice in Euhomy models, especially after using bottled mineral water. Vinegar cleaning alone often fails because users skip critical rinsing steps that protect nickel-plated components.

Vinegar Descale Process That Actually Works

- Unplug and empty the machine completely—remove all slush and residual ice

- Prepare solution: Mix equal parts white vinegar and distilled water (never tap water)

- Fill reservoir to the MAX line and run a full clean cycle

- Discard all output—this slush contains dissolved minerals

- Rinse twice with fresh distilled water using full reservoir cycles

- Wipe interior with soft cloth to remove loosened debris

Critical Warning: Skipping the double rinse leaves acidic residue that corrodes the evaporator plate. One user’s unit failed permanently after vinegar residue ate through the nickel plating—always rinse thoroughly.

Water Filter Replacement Protocol

If your Euhomy has a filter, replace it immediately if over 6 months old or after 300 gallons. Expired filters accelerate scale buildup even with vinegar cleaning.

- Remove filter and check for yellow/brown discoloration

- Install new filter and switch to distilled water exclusively

- Track replacement dates—set phone reminders every 6 months

Units without filters must use distilled water only. Bottled spring water contains 50–200 ppm minerals that cause slush within weeks.

Correct Temperature Settings for Solid Ice Production

Your ice maker’s thermostat may terminate the freeze cycle too early if sensors are coated or settings drift. Lowering the temperature forces longer freezing times—critical for overcoming minor mineral buildup.

Precise Temperature Adjustment Steps

- Locate dial behind front panel or inside ice storage compartment

- Turn counter-clockwise one full increment (do not force beyond stops)

- Mark original position with tape for easy reset if needed

- Wait 24 hours—temperature changes take a full day to stabilize

- Test ice solidity after 6 complete harvest cycles

Pro Tip: Ambient room temperature affects internal cooling. If your kitchen exceeds 80 °F, lower settings by two increments instead of one. Never set below manufacturer minimums—this strains the compressor.

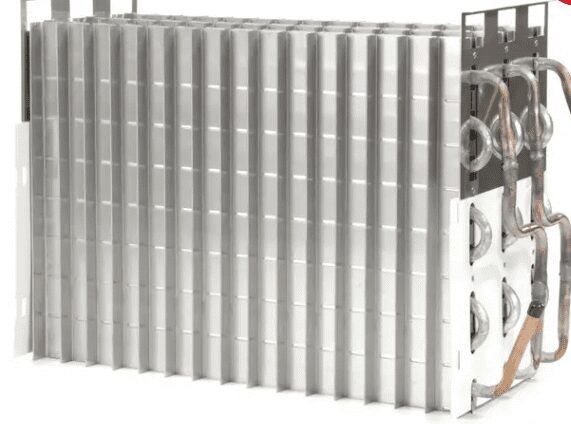

Clean Condenser Coils to Restore Cooling Capacity

Dirty condenser coils prevent heat rejection, causing evaporator temperatures to hover above 15 °F. This is especially common in kitchen installations with less than 3 inches clearance. Restricted airflow directly causes slush formation even with clean evaporators.

Condenser Coil Cleaning That Prevents Overheating

- Unplug unit and wait 15 minutes for pressure equalization

- Remove rear grille with Phillips screwdriver (typically 2–4 screws)

- Vacuum debris from coil fins using brush attachment—hold nozzle 2 inches away

- Gently brush parallel to fins with soft-bristle toothbrush—never perpendicular

- Verify clearance—maintain 3+ inches behind and beside unit before reassembly

Clearance Failure Sign: If coils feel hot to the touch during operation, your installation lacks ventilation. Built-in units without rear cutouts will repeatedly overheat—relocate to open counter space immediately.

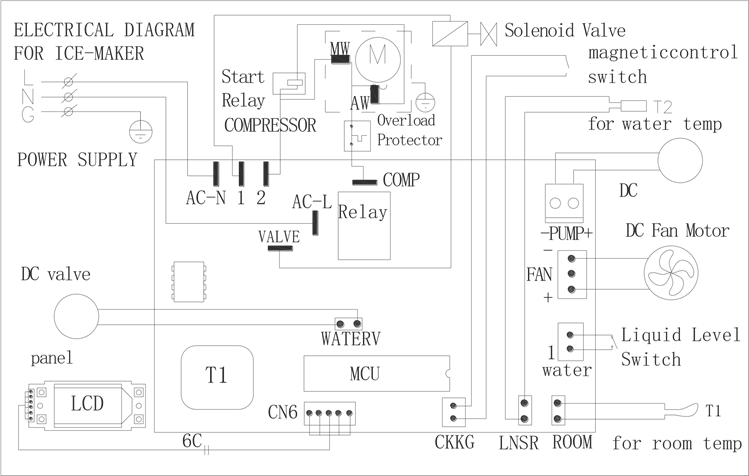

Diagnose Water Supply Issues Creating Thin Ice Layers

Insufficient water fill produces paper-thin ice sheets that melt into slush during harvest. The inlet valve may be clogged or the solenoid weakened from mineral exposure.

Water Level Verification Test

- Observe fill cycle—water should reach MAX line (120–150 mL)

- Measure with syringe if uncertain—less than 80 mL causes slush

- Inspect inlet screen—remove hose and check for sand/grit deposits

- Listen for solenoid click—weak “thud” instead of sharp “click” indicates failure

Emergency Fix: If water level is consistently low, unscrew the inlet valve and clean the mesh screen with vinegar. Replace the valve if flow doesn’t improve—this $15 part solves 70% of fill issues.

Execute 24-Hour Burn-In Protocol After Repairs

Rushing ice production after cleaning causes recurring slush. Your machine needs sustained operation to stabilize temperatures and flush residual vinegar.

Post-Cleaning Stabilization Steps

- Fill with fresh distilled water—never reuse cleaning solution

- Reset control board: Hold Power + Clean buttons 10 seconds until beep

- Discard first two harvests—they contain residual cleaner

- Run continuously for 24 hours without interruption

- Verify with thermometer—ice bin must read below 15 °F

Critical Checkpoint: If slush persists after 24 hours, place a calibrated thermometer in the bin. Readings above 15 °F confirm refrigerant or compressor failure—do not attempt further DIY repairs.

File Warranty Claim for Persistent Slush Issues

When slush continues despite perfect maintenance, internal components have failed. The Euhomy IM-12S-HM’s 12-month warranty covers compressor, sensor, and refrigerant issues—don’t pay for repairs you shouldn’t.

Streamlined Warranty Claim Process

- Record 30-second video showing slush output during harvest cycle

- Gather documents: Serial number (bottom of unit) and purchase receipt

- Email support@euhomy.com with subject: “Warranty Claim: Slushy Ice Failure”

- Include: Video, serial number, and description of all troubleshooting steps

Amazon Shortcut: If within 30 days of purchase, skip email and initiate exchange through “Your Orders.” Most users get replacement units in 3 business days versus 2+ weeks for repairs.

Prevent Future Slush Formation With Proactive Maintenance

Slush recurrence is 100% preventable with disciplined maintenance. Units using distilled water and regular coil cleaning never develop scale-related slush.

Daily: Use distilled water only—never bottled spring water

Weekly: Wipe interior surfaces with vinegar-dampened cloth

Monthly: Vacuum condenser coils during routine cleaning

Every 6 months: Replace water filter (if equipped)

Annually: Professional descaling service for hard-water areas

Pro Tip: Keep a maintenance logbook beside the unit. Note cleaning dates, water changes, and ice quality observations. Patterns emerge before slush appears—like reduced output after 5 months signaling filter replacement time.

Final Verification: If ambient temperatures exceed 85 °F, move your ice maker to a cooler location immediately. No amount of cleaning can overcome environmental heat that prevents the evaporator from reaching freezing temperatures. Your Euhomy IM-12S-HM requires at least 10°F room-to-evaporator differential—place it away from ovens, dishwashers, or direct sunlight for reliable solid ice production.